Composite Metal Foam (CMF) Armor Withstands Explosion of 23mm HEI Shells

About a year ago, Professor Afsaneh Rabiei of North Carolina State University developed composite metal foam (CMF) armor plates. In a test conducted in 2017, the 1″ thick plate performed impressively against small arms bullets and managed to get NIJ Level IV certification. You can find below the video footage of that test.

Recently, the NC State University has published an update on the CMF technology testing. Their joint tests with the U.S. Army’s Aviation Applied Technology Directorate showed that the CMF armor is capable of stopping the shrapnel from high explosive-incendiary (HEI) projectiles of 23x152mmB rounds. The most common weapon chambered in this caliber is the Soviet ZU-23 anti-aircraft double barrel autocannon which is widely used in current conflict zones in anti-materiel and anti-personnel roles. The goal of the test was to find out the composite metal foam’s capabilities in vehicle protection roles.

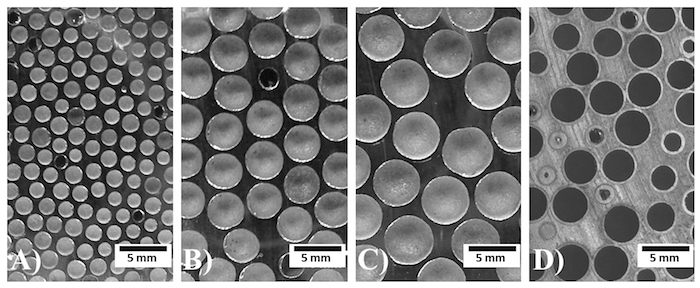

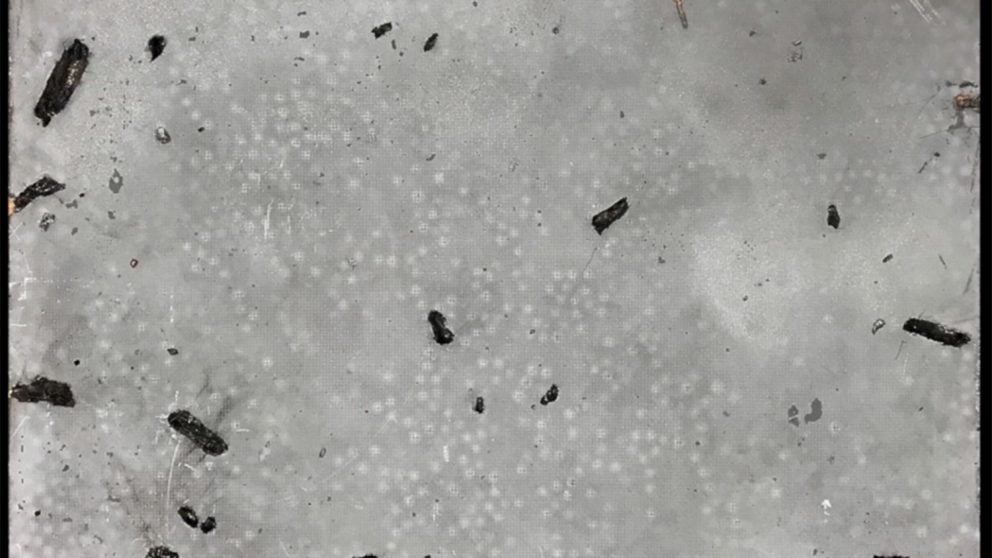

They fired a 23mm HEI round at a 2.3mm thick aluminum strike plate with 9.5mm and 16.75mm steel-CMF plates located at an 18″ distance behind the strike plate. The HEI shell exploded on impacting and penetrating the aluminum plate applying all the explosion force and shrapnel to the CMF plates. You can see that test in the video embedded below.

Both CMF plates managed to withstand the shockwave of the explosion. The thicker 16.75mm plate stopped all the fragments of the exploded projectile whereas the 9.5mm plate was penetrated by some of them. According to the researchers, a 10mm plate would have sufficient thickness to stop all the shrapnel fragments.

Here is what Afsaneh Rabiei said about this test:

In short, we found that steel-CMF offers much more protection than all other existing armor materials while lowering the weight remarkably. We can provide as much protection as existing steel armor at a fraction of the weight – or provide much more protection at the same weight.

Many military vehicles use armor made of rolled homogeneous steel, which weighs three times as much as our steel-CMF. Based on tests like these, we believe we can replace that rolled steel with steel-CMF without sacrificing safety, better blocking not only the fragments but also the blast waves that are responsible for trauma such as major brain injuries. That would reduce vehicle weight significantly, improving fuel mileage and vehicle performance.

The researchers will proceed to the next stages of testing where the composite metal foam plates will be tested against IEDs.

______________________________________________________________________________________________

Sources:

“Lightweight Metal Foam Blocks Blastwave, Debris From High-Explosive Rounds”. (2018, March 26). NC State University. Retrieved from: https://news.ncsu.edu/2018/03/metal-foam-he-rounds-2018/

Images from www.ncsu.edu