Metallic Wood: New Material That Is As Strong As Titanium But 5 Times Lighter

Metallic Wood is the name of a new material that is developed by the scientists of University of Pennsylvania’s School of Engineering and Applied Science, the University of Illinois at Urbana–Champaign, the University of Cambridge, and Middle East Technical University in Ankara, Turkey. Although it’s not a new element and basically consists of nickel, it is four to five times lighter than titanium thanks to its unique porous construction which is similar to natural materials such as wood: hence the name Metallic Wood.

The study was led by James Pikul, Assistant Professor in the Department of Mechanical Engineering and Applied Mechanics at Penn Engineering. Here is what he had to say about this material:

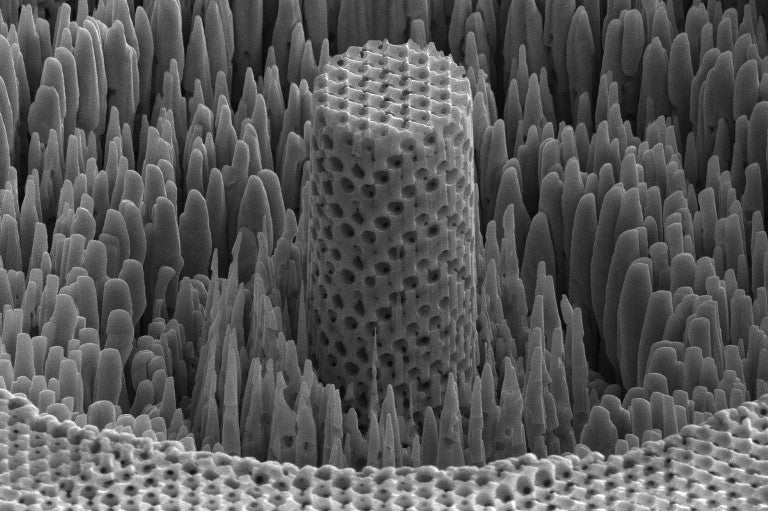

The reason we call it metallic wood is not just its density, which is about that of wood, but its cellular nature. Cellular materials are porous; if you look at wood grain, that’s what you’re seeing — parts that are thick and dense and made to hold the structure, and parts that are porous and made to support biological functions, like transport to and from cells.

Our structure is similar. We have areas that are thick and dense with strong metal struts, and areas that are porous with air gaps. We’re just operating at the length scales where the strength of struts approaches the theoretical maximum.

One of the key elements of such an impressive result is that the structure of the material is as close to perfect as possible. Imperfections in the structure are what make many materials such as titanium less stronger and prone to failure than they could potentially be if they had a perfect structure. The technology of making the Metallic Wood is quite interesting. Here is how it is described by Penn Engineering:

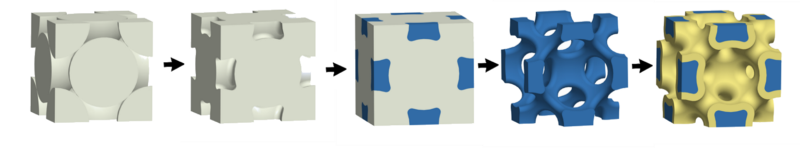

Pikul’s method starts with tiny plastic spheres, a few hundred nanometers in diameter, suspended in water. When the water is slowly evaporated, the spheres settle and stack like cannonballs, providing an orderly, crystalline framework. Using electroplating, the same technique that adds a thin layer of chrome to a hubcap, the researchers then infiltrate the plastic spheres with nickel. Once the nickel is in place, the plastic spheres are dissolved with a solvent, leaving an open network of metallic struts.

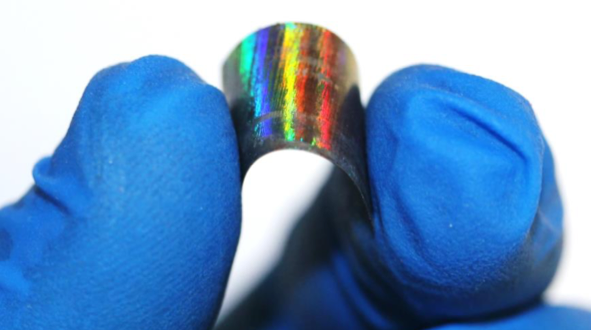

The struts in the Metallic Wood are around 10 nanometers wide (about 100 nickel atoms across). Penn Engineering admits that although materials with such a structure and precision can be built by 3D printing, their method is much faster and more flexible in terms of scalability. However, the characteristics and behavior of larger size objects made of this material are yet to be studied. Currently, they have made a foil from this material.

The pores make the 70% of the Metallic Wood which makes its density close to that of water. This feature may allow the material to float. Additionally, the pores can be filled with other materials such as energy storing substances. The latter would allow having various devices whose bodies double as batteries. Another potential advantage of this material could be its cost because it is made of relatively cheap nickel. Of course, that would be possible if the manufacturing technology is made cost-effective, too.

From the standpoint of the defense and firearms industries, if such a material can be built to a sufficient thickness, matching the claimed characteristics and at a reasonable cost, it may allow developing a wide variety of revolutionary new products: body and vehicle armor, small arms, projectiles, unmanned vehicles, fighter jets, submarines … you name it. Let us know in the comments section what do you think can be made using the Metallic Wood?

Sources:

“Penn Engineer’s ‘Metallic Wood’ Has the Strength of Titanium and the Density of Water”. (2019, January 24). Penn Engineering. Retrieved from: https://medium.com/penn-engineering/penn-engineers-metallic-wood-has-the-strength-of-titanium-and-the-density-of-water-a8d8573c6bc

The full study is published on the Nature Scientific Reports website.