In Profile: The M1 Abrams Main Battle Tank

With an estimated 10,000 built and still the primary Main Battle Tank (MBT) of the United States Army, the M1 Abrams remains one of the most formidable tanks in service, even though it first entered production over forty years ago.

Named after General Creighton Abrams, former Army Chief of Staff and a commander of armored forces described by General Patton himself as “…the world champion,” the M1 has managed to stay a tank to be reckoned with.

Combining excellent mobility with cutting edge firepower and electronic suite, the M1 Abrams has also demonstrated its ability to maintain and improve its lethality and efficiency with updates and modifications over the decades that keep it a match for any opposition.

Background

As early as the 1960s the U.S. Army recognised the need for a new model of tank to meet its future combat requirements. The primary US tank at that time, the M60, was an evolutionary development of the M48 Patton, which in turn was ultimately derived from the M26 Pershing of the late Second World War.

A development program was launched in co-operation with West Germany who also recognised that a new tank would be needed within the next decade or so in order to maintain at least parity with the vast Soviet tank fleet that was considered NATO’s primary land threat.

This project, the MBT-70, proved overly ambitious and ultimately was cancelled in 1971 after major cost overruns. In 1972 a new program was started. By now developments in Soviet tank design meant that the M60 was becoming out-classed by potential enemies such as the T-64 and T-72 and fielding a new tank was imperative.

Further impetus was given following the 1973 Yom Kippur War, which saw the Israeli armoured corps take fearful losses amongst their American and British-origin tanks, primarily from cheap and lightweight Soviet-supplied anti-tank weapons such as the AT-3 Sagger and RPG-7.

The war made a major impression on the US Army, transitioning at that time from the war in Vietnam back to a more conventional focus. The Army appreciated that not only had the Arab armies plentiful use of modern anti-tank weapons demonstrated how vulnerable their own M48 and M60 tanks were, but also the tanks of potential enemies.

This led to a new philosophy within the US Army’s command. Instead of a reliance on atomic weapons for the defense of NATO, a conventional force approach offered the possibility of blunting a Warsaw Pact attack without the potential dangers of a nuclear war. This strategy was adopted by the U.S. Army in 1976 with the “Active Defense” doctrine and refined further into the “AirLand Battle” concept that was adopted in 1984.

Both these concepts required highly mobile and powerful new vehicles, capable of overmatching enemy vehicles and withstanding the effects of anti-tank weapons. The evolution of these fighting doctrines went hand-in-hand with the development of the M1.

Development

The U.S. Army laid requirements for the new MBT in 1972 and reassessed them in the light of Yom Kippur in 1973. The revised specification called for an increase in weight to 60 tons (54 tonnes), fitting of the new British-developed “Chobham” composite armor and an M68 105mm rifled cannon.

Both Chrysler Defense and General Motors were issued contracts to develop prototype vehicles for what would be designated the XM1. These were delivered for testing in 1976. Both vehicles had a similar layout due to the slab-like appearance of their armor, but utilised different automotive technologies; the GM XM1 had a diesel engine whilst Chrysler’s entry had a gas turbine. This made the GM tank more fuel-efficient but the Chrysler had the ability to access huge amounts of immediate power with its turbine.

Though innovative, the Chrysler tank was beaten during the Army’s trials by the GM model. This was set to become the next U.S. Army MBT, but in July 1976 the decision was blocked by the Secretary of Defense, Donald Rumsfeld, and Chrysler was ultimately awarded the contract instead.

Design Features

Armament:

The cannon fitted to the early Abrams (M1 and M1IP versions) was the M68A1 105mm rifled gun, an updated version of the same gun used by both the M60 and the upgraded M48. This gun was a licence-built copy of the British Royal Ordnance L7.

The development of more advanced 105mm rounds like the Depleted Uranium (DU) penetrator M833 round meant the 105 mm was to remain viable despite the fielding of advanced Soviet tanks such as the T-64 and T-72.

However, during the prototype stage of the M1s development, the specification had been laid for the eventual arming of the Abrams with a 120mm cannon in the future. In 1985 it was decided to up gun the M1, creating the M1A1 (see Models below).

After examining both the British L11 rifled gun and the German Rheinmetall L44 120mm smoothbore, as used by the Leopard 2 series, the latter was chosen to provide the basis for the M1s new primary weapon, the M256. This gun arms the majority of the Abrams in service now as many of the early models were rebuilt with new turrets and armament.

The tank’s secondary armament comprises of an M2 Browning .50 caliber heavy machine gun, mounted on the Commander’s Weapons Station which allows it to be aimed and fired from within the tank. Two 7.62x51mm M240 machine guns are also fitted as standard: one in front of the loader’s hatch and the second coaxially to the right of the main gun.

One of the most critical aspects to the success of the M1 was that it was designed from the beginning with an integrated electronic Fire Control System. This sees a Hughes laser rangefinder combined with a ballistics computer that takes into account variables such as ammunition type, lead angle measurement, turret position, gun distortion and wind velocity to provide a fire solution that has proven in combat capable of killing tanks out to 4,000 metres.

Protection:

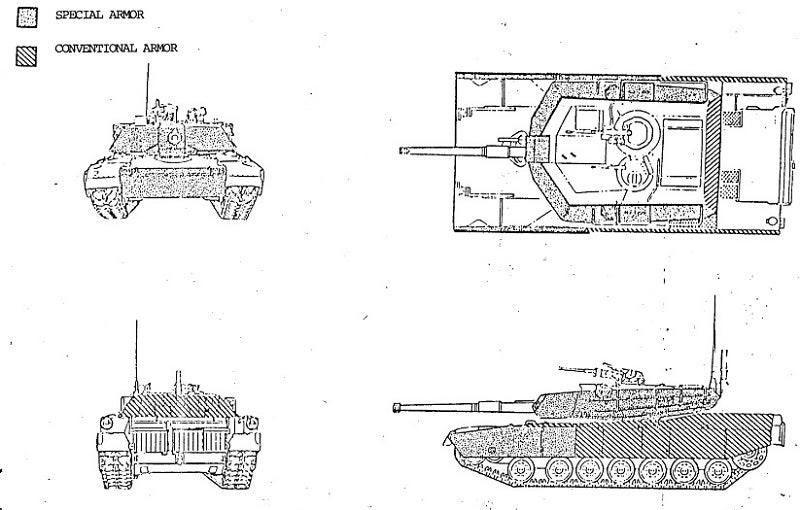

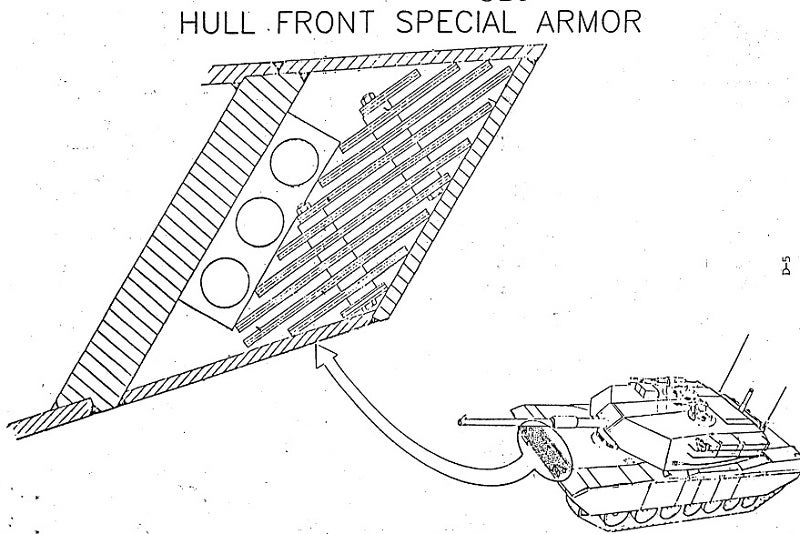

Whilst the rear hull of the M1 is made from RHA steel, the turret, glacis and hull forward quarter is protected by Chobham composite armor.

This is composed of ceramic tiles encased within a metal lattice and bonded to a backing plate and several elastic layers. The hardness of the ceramics offers superior resistance against shaped charges such as high explosive anti-tank (HEAT) rounds and also the ability to shatter the kinetic energy penetrators of APDS/APFSDS projectiles from certain angles.

A layer of RHA provides the outer skin to the interlayered composition and the Abrams also features Kevlar spool liners inside the vehicle designed to stop any fragments sheared off internally by blast damage that may otherwise injure the crew.

Though developed by the British in the early ‘70s, the Abrams was the first production tank to field the new composite armor. However, though Chobham is highly effective against HEAT warheads, it’s resistance to kinetic penetrators was rapidly degraded by developments in Russian tank projectiles. This led to U.S. developers creating a version which integrated a Depleted Uranium (DU) alloy into the armour composition. This exceptionally dense metal provides far greater resistance to kinetic penetrators and was used in the M1A1 (HA) model onwards.

In case of fire inside of the tank a halon automatic fire extinguisher system is fitted. There is a manually operated fire suppression system for the engine compartment which is activated by the crew.

Fuel and ammunition are stored in armored compartments with blowout panels to prevent internal explosions if hit. Additionally, the main gun’s ammunition is stored in the rear turret bustle which is provided with blast doors. The M1 is also fitted with a full Nuclear/Biological/Chemical (NBC) defensive system that provides filtered air via the air conditioning.

Propulsion:

As already stated, the Lycoming (later Honeywell) AGT 1500 multi-fuel gas turbine is the unique engine choice for the M1. Delivering 1,500 shaft horsepower (1,100 kW) it runs via a six-speed (four forward, two reverse) Allison automatic transmission. Top speed was 45 mph (72 km/h) on paved roads and 30 mph (48 km/h) cross-country with a governor in the early models, reduced to 42 mph and 25 respectively on later, heavier models.

Such performance figures were a revelation to crewmen used to the more sedate M60, which weighed only slightly less than the first models of M1 but had only about half the horsepower.

As a multi-fuel engine, the AGT 1500 can run on diesel, kerosene, gasoline and high-octane jet fuel. The primary issue with this engine is its very high fuel consumption. The early models are listed as requiring 1.67 US gallons (6.3 L) for each mile or 60 US gallons (230 L) per hour on flat roads. This increases substantially when moving cross-country.

Major Models

A host of different variants of the M1 Abrams have seen production and use, but the principle combat models are as follows:

M1 / M1IP

A total of 3,273 M1 Abrams tanks were produced between 1979 and 1985, entering U.S. Army service in 1980. This model had the 105mm M68 cannon, a Browning M2 heavy machine gun in the commander’s cupola and two M240 7.62x51mm machine guns, one mounted coaxially and the other mounted above the loaders hatch.

These tanks would prove a vast improvement over the M60s they gradually replaced in front line formations in Europe. The first modifications to improve the tanks survivability further were made in 1984 with the fielding of about 840 M1IP (Improved Protection) which saw the introduction of a new, longer turret and Kevlar armour bulkheads separating the crew compartment from the fuel tanks and ammunition stowage.

M1A1 / M1A1 (HA)

The first major upgrade occurred in 1985 with the fielding of the M1A1. This was fitted with a U.S. variant of the German Rheinmetall L44 120mm smoothbore manufactured under licence.

This gun had been proposed for the Abrams since 1976 but problems delayed its introduction and installation for almost a decade. However, it soon became the standard, with around 5,000 M1A1s built between 1985 and 1992.

Before production of the A1 ended in 1992 a number of improved models were fielded, most noticeably the M1A1 (HA) which features the improved Chobham armor with Depleted Uranium.

M1A2

The most numerous variant in service today – with many earlier models bought up to this standard – the M1A2 combines the various improvements over the different M1A1s. It also features a brand new Fire Control System, a commander’s independent thermal viewer and weapon station, battle management equipment and displays integrated with a digital data bus.

The A2 has also seen progressive upgrades over the last two decades, principally improvements to the armor and thermal imaging systems as well as installation on some tanks of Remotely Operated Weapon Stations and the Tank Urban Survival Kit (TUSK). This upgrade was in response to the lesson of the Iraq War and saw the fitting of Explosive Reactive Armor blocks on the side skirts to defend against ATGMs, as well as slat armor on the rear to protect against RPGs and other shaped charge warheads. Transparent bullet proof screens were also applied to the turret roof machine guns.

M1A2C

The modernization of the M1A2, previously known as the M1A2 Systems Enhancement Program Version 3 (SEPv3) introduces a number of new features. The new features include an improved armor package and an improved fire control system with an ammunition data link for use with newer data linked ammunition like the M829A4 APFSDS shell and XM1147 Advanced Multi Purpose programmable high explosive shell. The electricity generation capacity of the tank has also been improved in order to facilitate the installation of new systems and meet their electrical demands. These new systems include the Trophy hard-kill active protection system and improved communications and networking hardware.

The 3rd Battalion, 8th Cavalry Regiment, 3rd Armored Brigade Combat Team (3ABCT), 1st Cavalry Division, part of the Greywolf brigade, were the first to receive the M1A2C.

Users / Service

Australia – 59 M1A1

Egypt – 1,360 M1A1

Iraq –Between 2010 and 2012 the U.S. supplied 140 refurbished M1M Abrams tanks to Iraq. Used in action against ISIS in 2014-2017 around 30 of these Iraqi M1s were captured by ISIS after being abandoned by their crews. In December 2014 the U.S. Department of State approved the sale of another 175 Abrams to Iraq.

Saudi Arabia – 373 Abrams tanks upgraded to M1A2S configuration in Saudi Arabia. 69 more M1A2S were reportedly delivered in July 2014. In August 2016, the U.S. approved a deal to sell up to 153 more Abrams tanks to Saudi Arabia, including 20 “battle damage replacements.

Kuwait – 218 M1A2s

Morocco – 222 M1A1 tanks ordered in 2015, deliveries starting the next year.

United States – United States Army and United States Marine Corps have received over 8,100 M1, M1A1 and M1A2 tanks combined. These have seen service in multiple conflicts:

Desert Storm (1991)

The response to the Iraqi invasion of Kuwait in 1990, Operation Desert Storm was the first operational deployment of the M1. Facing against a mix of older tanks, predominantly T-55, T-62s, T-72s from ex-Soviet and Polish stocks, the Abrams proved overwhelmingly superior. A total of nine Abrams were destroyed, seven by friendly fire. By contrast, over 250 Iraqi tanks were claimed.

Operation Iraqi Freedom (2003)

The invasion to topple Saddam Hussein saw at least nine Abrams tanks put out of action by fire from rocket-propelled grenades. However, the tank proved critical for the rapid invasion, able to maintain a high tempo of operations against the disintegrating Iraqi army.

The subsequent occupation and years of fighting to attempt to stabilise the country saw the Abrams used to provide heavy fire support to troops. Dozens of tanks have been destroyed and several hundred have required substantial repair in the United States, normally due to IED ambush. However, the M1 has shown itself extremely resistant to all but the latest anti-tank weapons.

Afghanistan

A small detachment of 14 USMC M1s were deployed in 2011 to provide forces in Helmand and Kandahar with additional heavy firepower.