AUSA 2024: Revolutionizing Resupply with Kaman’s KARGO UAV

As the US military prepares for conflict scenarios in the Pacific, logistics is one of the greatest challenges facing planners. Supplies must be transported across vast distances to small, forward-deployed units which could be distributed between islands hundreds of miles apart. Moreover, for the first time in decades, the US is likely to face a contested logistics environment.

At AUSA 2024, Kaman displayed its autonomous KARGO drone which seeks to address these challenges by providing a new medium-lift UAV capability which will meet the US military’s future force requirements. Currently, KARGO is still in the development stage, and is undergoing trials with Army and Marines.

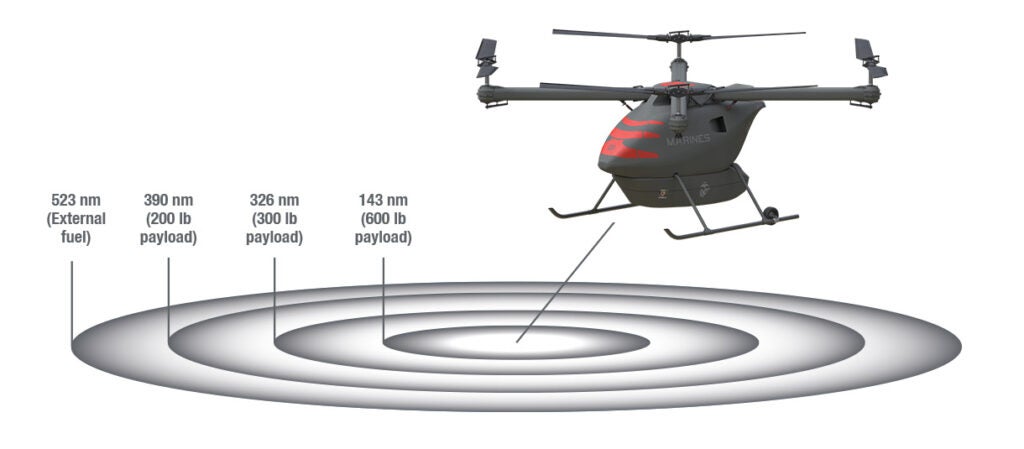

The drone is capable of carrying up to 800 pounds of cargo (360kg) and flying up to 600 miles (970km) when unburdened. The final production version should be capable of flying 350 miles (560km) with a load of 300lbs (135kg). However, for logistics at the theater level, what matters is reliable throughput – not the speed of a single delivery.

“It’s not just about how fast can you fly the airplane, it’s more about how much equipment or how much resupply can you move within a given period of time,” KARGO General Manager Romin Dasmalchi told Overt Defense. This means putting a focus on affordability, reliability, and maintainability.

“Rule number one is keep it simple. KARGO is designed with the highest TRL [technology readiness level] components that we can find. Yet we need to be able to put the latest technologies in terms of autonomy and avionics and things like that. So we use the Rolls-Royce 300 turbine engine. We drive all four rotor systems mechanically. This is not a distributed electronic system at all. So we use fossil fuel for our purposes, for the ruggedness, for the distances, for the reliability that we need, we choose to go with an engine like that, that’s literally got millions of flight hours on it, so we know the reliability factor”.

This simplicity also extends to user experience. KARGO is meant to be as simple to interact with for users as possible.

“At the end of the day, you want your Soldiers or Marines to really focus on their mission, their number one mission, not flying a drone. So they would simply answer a query that comes from the drone that says are you ready to receive a resupply, yes or no? And if you say no, then it’s going to enter ‘hold’ and wait. If you say yes, it’s going to come in and drop precisely where you want it to drop.”

For maximum efficiency, the system is also easily transportable and quick to assemble. It can be stored inside a standard 20-foot shipping container and go from storage to flight-readiness in just 10 minutes. KARGO also takes into account that space on ships is limited; drones can be based at a third location and only fly to a ship when they are needed to drop off or pick up a delivery.

“We want to provide something with enough range that will allow it to solve the logistics problem, not create a new one. So, for example, you don’t really need to store these on board your ships. That real estate is extremely valuable for your other warfighting high-end equipment, like the F-35 or the V-22 Osprey. Those types of aircraft will be operating frequently around your amphibious ships and carriers.”

This also means that the drone must be capable of landing on and taking off from ships:

“We’ll go through some pretty rigorous testing for at-sea trials – eventually landing on ships. It needs to be interoperable with ships. […] That’s one reason why we choose a rotorcraft over a winged aircraft right, you can get into more tight confined spaces with this. You can land in much more harsh environments.”

The system is also very flexible in terms of what equipment it can carry; the standard configuration would have the payload attached externally under the drone.

“There’s a central hook-mounted system. You could choose to do a long-line package if you like… The other option is an informal pod. We have a few pod concepts. I mean, if you can carry 800 pounds, you can sort of use your imagination. What would you like to put on there? We have concepts for medical evacuation, for example. Because we use turbine power, we can generate a lot of electricity with the right size generator. We’ve done a few studies. We have a lot of options. You can run an environmental control system. So if you do have a casualty on board, or if you need to run equipment on board, if you have an electronic payload and you need more power, there are a lot of options when you go with proven technology like turbine power.”

Together with other programs like DARPA’s liberty lifter, KARGO demonstrates what the future of logistics is likely to look like. Kaman has been a pioneer in rotary aviation since 1945 and KARGO demonstrates they have not lost their edge.